| | |

Classic Chinese furniture is unique for many reasons, including its exquisite carvings, rare woods and joinery. Each type has joints that are suited for the particular strains and stresses that will be placed on it.

Understanding joinery and construction further enhances the connoisseurship of Chinese hardwood furniture. To the aesthetically inclined observer, the study of joinery may seem at first an unusual approach, yet the techniques employed play an important part in the overall effect. The animation and harmony experienced when viewing masterpieces is often the result of a unity that lies beneath the surface  members are not only connected together to form a functional object, but also manifest integrated conceptualization. Techniques of wood joinery were born from an ancient technological culture and developed through continuous evolution of timber architectural systems. Further heights of sophistication and refinement were reached during the Ming and early Qing dynasties along with the manufacture of hardwood furniture. members are not only connected together to form a functional object, but also manifest integrated conceptualization. Techniques of wood joinery were born from an ancient technological culture and developed through continuous evolution of timber architectural systems. Further heights of sophistication and refinement were reached during the Ming and early Qing dynasties along with the manufacture of hardwood furniture.

An almost infinite combination of joints is possible in Chinese furniture. Familiarity with the major types and typical aplications is essential for anyone interested in Chinese furniture. It is important to remember that joinery should be consistent, and construction logical. If it is not , there is a good possibility that the object is a copy or that it has been altered.

The most basic joint in Chinese cabinet making is the mortise and tenon.

A mortise is a cut-out receptacle. A projection from the piece to be attached fits into the mortise.

There are many types of mortise-and-tenon joints. In the most basic - the butt-joined mortise and tenon - the ends of both the members to be joined are squared. If the ends are cut at an angle, it is called a mitered joint. A joint can be mitered on only one side or on both sides. There are many types of mortise-and-tenon joints. In the most basic - the butt-joined mortise and tenon - the ends of both the members to be joined are squared. If the ends are cut at an angle, it is called a mitered joint. A joint can be mitered on only one side or on both sides.

Frame-and-panel Construction

The 'frame-and-panel' evolved as a more efficient use of material, and is typical of most panels in Chinese furniture, whether tabletop, door, or cabinet panel. The frame is joined with mitered, mortise-and-tenon joints. A groove is cut around the upper, inside edge of the frame, while the panel is shaped with a corresponding tongue around its outside edge.

This 'tongue-and-groove' system secures the panel within the frame without glue or nails and permits the panel to float within the frame to accommodate its slight expansion and contraction due to changes in humidity. Additionally, transverse braces¡ªwhose number depends on the length of the panel¡ªslide into shallow dovetail housings cut into the bottom of the panel, both supporting the thin panel and preventing its warping.

Recessed-leg Construction

The practical and minimalistic 'recessed-leg' form was established by the Song dynasty and continued to be reproduced throughout the Ming and Qing dynasties. This basic construction pattern, which was closely related to traditional post-and-beam architecture, was commonly applied to the creation of stools, chairs, tables and cabinets. dynasty and continued to be reproduced throughout the Ming and Qing dynasties. This basic construction pattern, which was closely related to traditional post-and-beam architecture, was commonly applied to the creation of stools, chairs, tables and cabinets.

The 'recessed-leg' technique employs legs joined at points inset (or 'recessed') from the corners of a mitered frame. The legs generally splay outward toward the base, and are connected by various configurations of stretchers and/or aprons. The aprons in this example are joined to the single-piece spandrel heads with a blind dovetail. Double tenons on the top of each leg fit into the underside of the frame.

Corner Leg Construction

orner-leg construction can be divided into 'waisted' and 'simianping' (literally flush-sided) styles. The corner-leg form is self-descriptive with legs generally set flush to  the corners of the top frame. The legs can be of straight, c-curved, or cabriole style; they typically terminate with some a horsehoof or variation of ruyi -shaped motif, animal claws, or scrolled foot. the corners of the top frame. The legs can be of straight, c-curved, or cabriole style; they typically terminate with some a horsehoof or variation of ruyi -shaped motif, animal claws, or scrolled foot.

Furniture of 'waisted' style retains architectural characteristics of the classical Greek pedestal, which migrated eastward to Gandhara where, as a dignified support, it became associated with the seat of Buddha. As Buddhism spread into China, so did the classical pedestal form. Early tables of 'high-waisted' form tended to be used for religious or ceremonial purposes. By the late Ming period, waisted furniture had become incorporated into the common vernacular of furniture design.

Early furniture of this style commonly required intermediate or base stretchers for reinforcement, and decorative taohuan panels were fitted to the 'high-waist' section. During the late Ming period, the development of sophisticated joints with dovetail keys permitted the abandonment of supplementary braces and stretchers. The waist section can be various design. Sometimes it is one piece with the apron as illustrated here; sometimes it is a separately joined to the apron with dovetail wedges from the back; alternatively, it may be comprised of early-style taohuan panels. The use of supplementary giant's arm braces, humpback stretchers, or decorative spandrels is also common to cornerleg furniture.

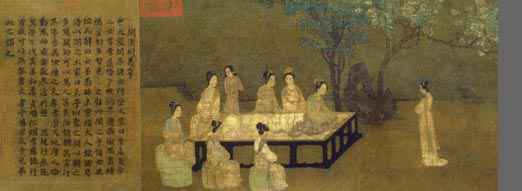

Simianping forms likely developed from early box-style constructions, whose use as tables and platforms are evident in Tang period paintings. Tables, beds, and stools of minimalistic, simianping-style were produced as early as the Song dynasty, and remained popular throughout the Ming dynasty. Such flush-sided tables that could be placed side-by-side were also convenient for creating large banquet arrangements. The configuration of simianping corner joints differ from those of  waisted construction because of the greater apron thickness. In this variation, long tenons are shaped onto the leg members penetrate through the aprons and into the seat frame or table top. waisted construction because of the greater apron thickness. In this variation, long tenons are shaped onto the leg members penetrate through the aprons and into the seat frame or table top.

Bamboo-style Construction

ome of the earliest Chinese furniture was made from common bamboo. However, the use of hardwood or lacquered softwood to simulate the construction of bamboo furniture was popularized during the transitional 17th century, and likely entered into the mainstream during the Qing dynasty when the imitation of materials and finishes was practiced throughout the decorative arts.

'Bamboo-style' furniture employs rounded, bamboo-like members that are configured to simulate the wrap-around and layered construction techniques of furniture made from real bamboo. Sometimes the members are smooth without carving; sometimes they are carved with bamboo-like nodes. This category, which has its own logic and origins, falls somewhere between the traditional systems 'recessed-leg' and 'corner-leg' construction.

|

members are not only connected together to form a functional object, but also manifest integrated conceptualization. Techniques of wood joinery were born from an ancient technological culture and developed through continuous evolution of timber architectural systems. Further heights of sophistication and refinement were reached during the Ming and early Qing dynasties along with the manufacture of hardwood furniture.

members are not only connected together to form a functional object, but also manifest integrated conceptualization. Techniques of wood joinery were born from an ancient technological culture and developed through continuous evolution of timber architectural systems. Further heights of sophistication and refinement were reached during the Ming and early Qing dynasties along with the manufacture of hardwood furniture.

dynasty and continued to be reproduced throughout the Ming and Qing dynasties. This basic construction pattern, which was closely related to traditional post-and-beam architecture, was commonly applied to the creation of stools, chairs, tables and cabinets.

dynasty and continued to be reproduced throughout the Ming and Qing dynasties. This basic construction pattern, which was closely related to traditional post-and-beam architecture, was commonly applied to the creation of stools, chairs, tables and cabinets. the corners of the top frame. The legs can be of straight, c-curved, or cabriole style; they typically terminate with some a horsehoof or variation of ruyi -shaped motif, animal claws, or scrolled foot.

the corners of the top frame. The legs can be of straight, c-curved, or cabriole style; they typically terminate with some a horsehoof or variation of ruyi -shaped motif, animal claws, or scrolled foot. waisted construction because of the greater apron thickness. In this variation, long tenons are shaped onto the leg members penetrate through the aprons and into the seat frame or table top.

waisted construction because of the greater apron thickness. In this variation, long tenons are shaped onto the leg members penetrate through the aprons and into the seat frame or table top.